THE NEXTGEN CONSORTIUM

ACCELERATING THE CIRCULAR FUTURE OF FOODSERVICE PACKAGING

The Consortium brings leading brands, industry experts and innovators together to reimagine foodservice packaging, accelerating sustainable and circular solutions to reduce waste on a global scale.

The NextGen Consortium is a multi-year, global consortium that aims to address single-use foodservice packaging waste by advancing the design, commercialization and recovery of packaging alternatives. The Consortium works across the value chain––with brands, municipalities, material recovery facilities and manufacturers––to ensure we provide viable market solutions that scale throughout the supply chain and bring value to recovery systems.

Closing the Loop on Cups: Collective Action to Advance the Recovery of Paper Cups in the U.S.

This report focuses on paper cup recovery, assessing critical nodes of the paper cup recovery value chain to demonstrate how, together, key stakeholders can sustain a market for paper cup recycling.

Bringing Reusable Packaging Systems to Life: Lessons Learned from Scaling Reusable Cups

The report outlines key lessons learned and sharing a blueprint and open-source resource to encourage collaboration and the growth of reuse models.

Our Impact Areas

Our Activities

In the News

Press Release

New Report from the NextGen Consortium Shares Path…

Insights include solutions for paper mills, material…

Reuse

Blog Post

Debunking Durability: How Durable Does Reusable Packaging…

New reuse innovations are expanding what is possible,…

Reuse

Blog Post

When Reusable Cups Reach End-of-Life: 5 Tips to Ensure…

The NextGen Consortium shares 5 tips to ensure reusable…

Blog Post

How a South Carolina Paper Mill Started Recycling Your…

In July 2022, Sonoco announced it would accept paper…

Press Release

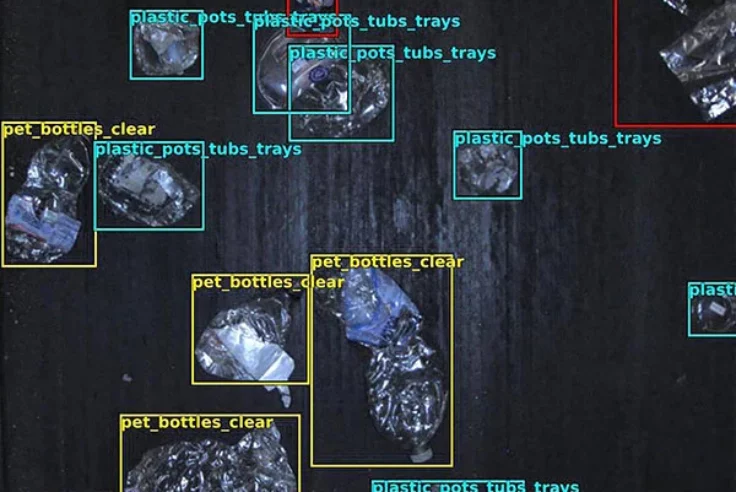

How AI Could Change the Way We Think About Recycling

Closed Loop Partners’ Center for the Circular Economy…

Press Release

Upstream and Closed Loop Partners Announce Finalists…

The Reusies: “The Oscars of the Reuse Movement”…

Blog Post

From 480 Innovative Submissions to 12 Sustainable Solutions:…

Four key drivers have accelerated sustainable packaging…

Press Release

Starbucks and McDonald’s Deploy Additional $10…

The Consortium expands its work to advance reusable…

Press Release

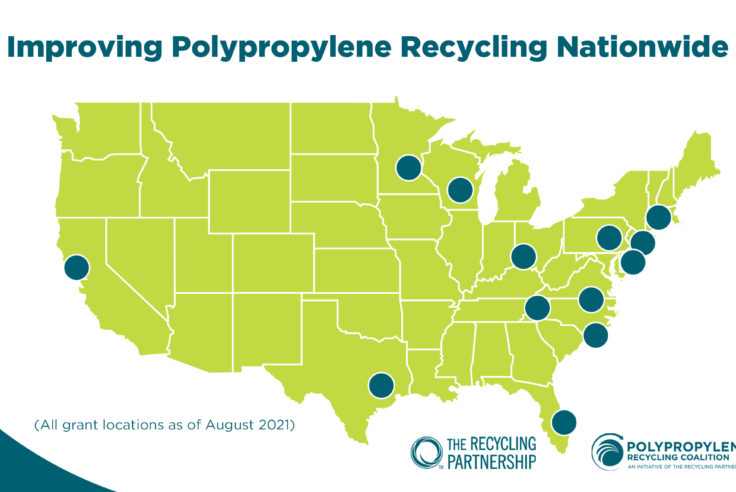

$4.2M in Grants Awarded to Improve Polypropylene Curbside…

In less than one year, The Recycling Partnership’s…

Media Coverage

Seattle Starbucks Stores Go Even Greener This Earth…

Two-month borrow-and-return trial will run in five…

Press Release

The Recycling Partnership Announces Three Grants to…

Polypropylene Recycling Coalition brings total awards…

Press Release

Closed Loop Partners Releases Groundbreaking Report…

January 14, New York – Today, the Center for the Circular…

Press Release

NextGen Consortium Joins the Polypropylene Recycling…

NextGen Consortium brings its collective strength and…

Blog Post

Two Georgia-Pacific Recycled Paper Mills Open Opportunities…

Georgia-Pacific announced today that it is now accepting…

Media Coverage

Starbucks Is Ready to Reintroduce Reusables Across…

Customers can safely use their reusable cups again…

Blog Post

Bringing NextGen Cups to Market: It Takes a Village

Local cafes, cities and students joined the NextGen…

Media Coverage

Starbucks Tests a Greener Cup

Paper cup features liner made out of biodegradable…

Media Coverage

Starbucks Is Testing a New Cup. Here’s What’s…

The new version of the cup is still made from paper,…

Media Coverage

Starbucks Begins Trialling New NextGen Cup in London

The world’s first market trials will begin on the…

Blog Post

The Journey to Innovate How We Drink on the Go: 2 Years…

This week, we hit a major milestone nearly two years…

Media Coverage

McDonald’s and Starbucks Back ‘Smart’…

The cities of San Francisco and Palo Alto are set to…

Media Coverage

Don’t Toss That Cup: McDonald’s and Starbucks Are…

Pilot programs in California that start this week will…

Press Release

NextGen Consortium Begins Piloting Sustainable Cup…

Local cafes join the Consortium’s efforts to advance…

Media Coverage

12 Winners of NextGen Cup Challenge Reimagining the…

Starbucks, McDonald’s and other industry leaders partner…

Blog Post

Bringing the NextGen Cup to Life

From 480 innovative ideas, to live prototyping, to…

Media Coverage

McDonald’s and Starbucks Pour Millions Into Eco-Friendly…

Earlier this year, 44 per cent of Starbucks shareholders…

Press Release

Six Companies Graduate from the NextGen Circular Business…

The NextGen Consortium, a pre-competitive collaboration…

Blog Post

How to Use Design Thinking to Advance Systemic Change,…

Amid burbling espresso machines and towering stacks…

Media Coverage

Will One of These 12 Visions Replace Today’s…

Some 600 billion new disposable cups each year swell…

Media Coverage

Starbucks Cups are Getting a Makeover — Here’s…

Your cup of java is changing its look and cleaning…

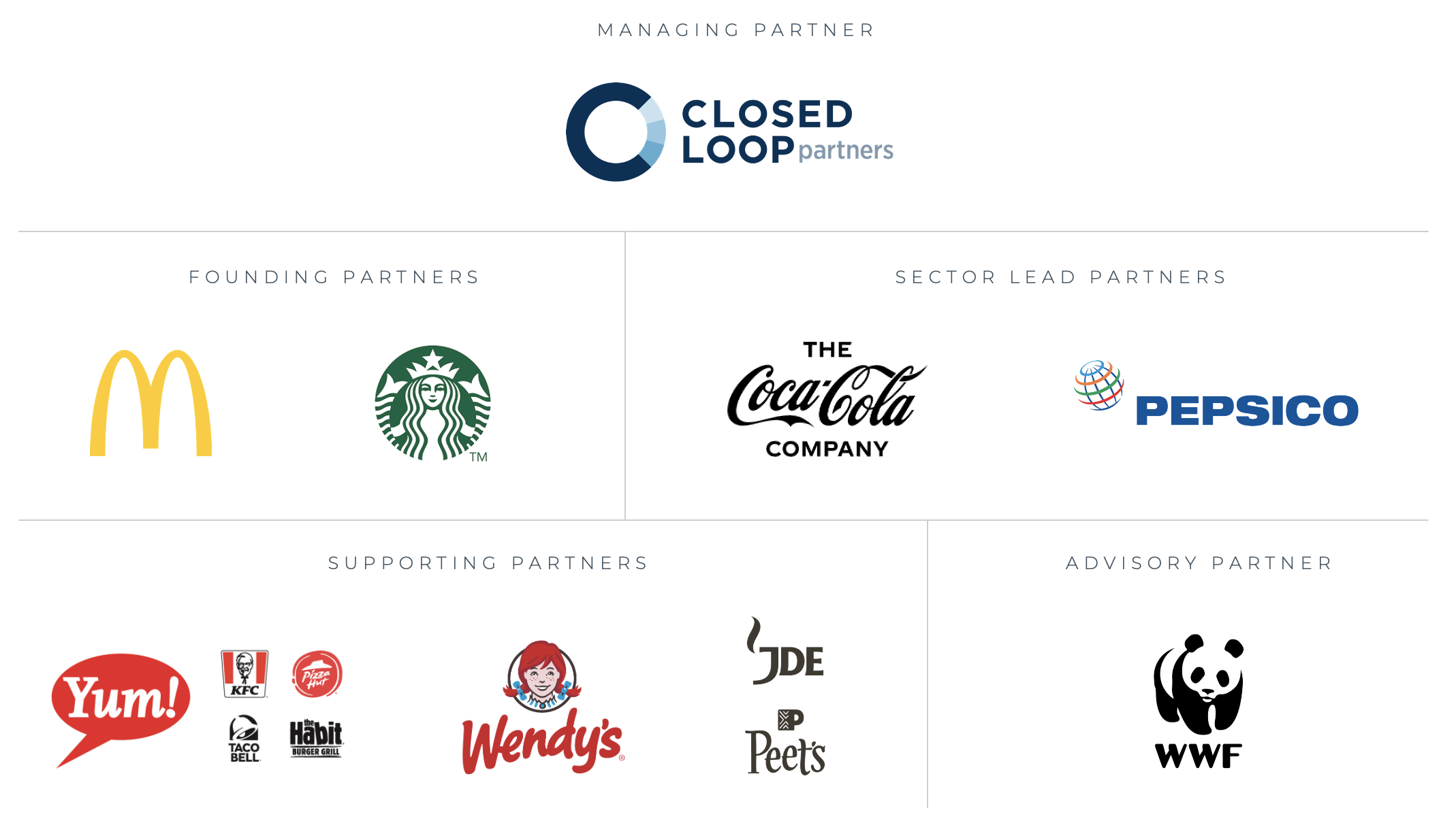

Consortium Partners